Project Objective

Research into new design and manufacturing solutions for floating offshore wind superstructures based on the introduction of new materials, welding technologies, surface treatments, intelligent inspection and digitalization not currently available in the sector.

These actions have been subsidized by the Ministry of Industry, Trade and Tourism through the Recovery and Resilience Mechanism and financed by the European Union-Next Generation EU in the framework of the aids to actions for the integration and transformation of the industrial value chain of the naval sector, within the Strategic Project for the Recovery and Economic Transformation for the modernization and diversification of the Spanish naval ecosystem (PERTE NAVAL).

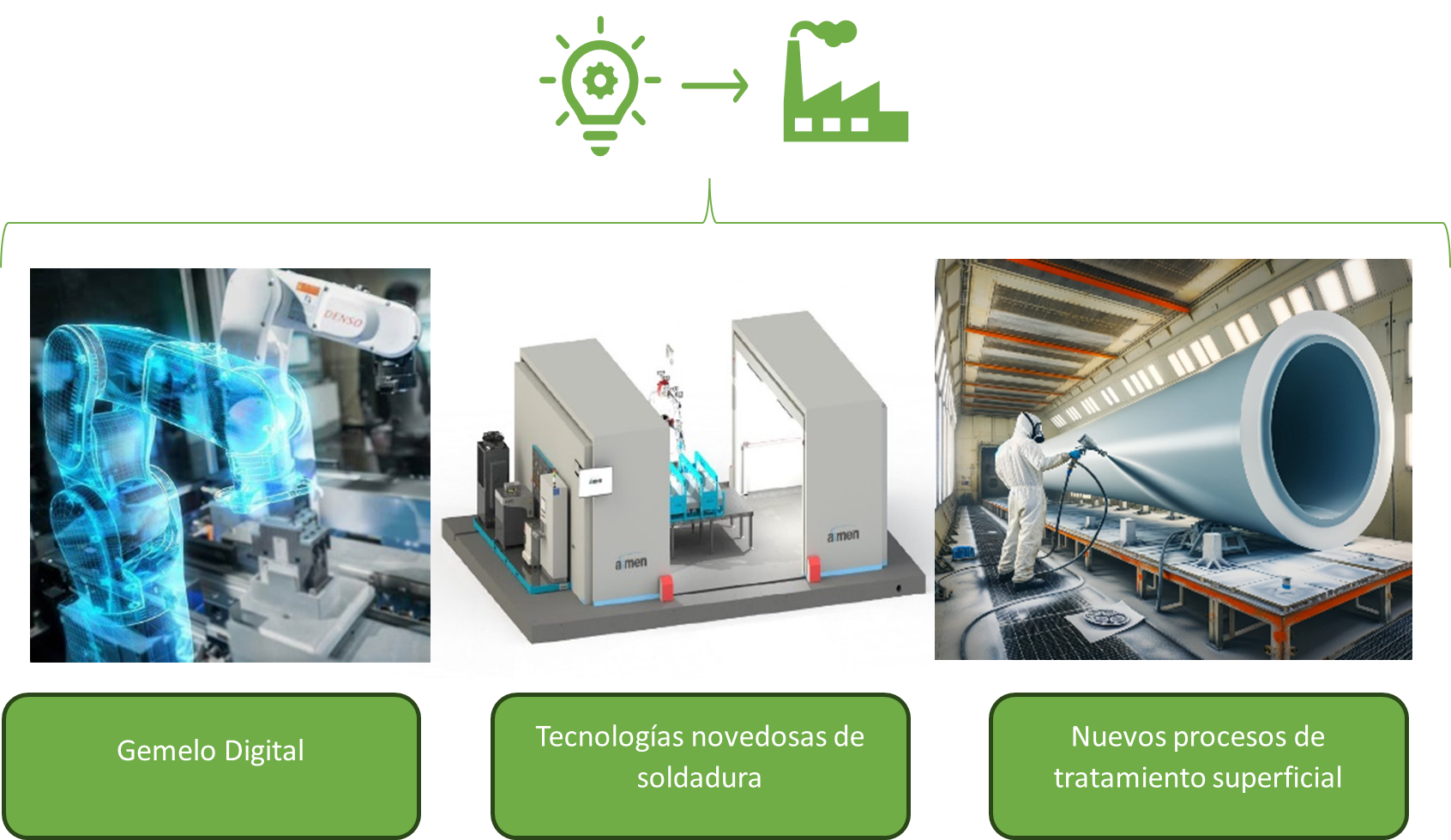

The implementation of the project will revolutionize the manufacture of marine superstructures for new generation wind turbines through the introduction of new advanced materials, innovative technologies in welding strategies and defect detection and improved surface treatment processes. This transformation, supported by digitalization and Industry 4.0 technologies, will optimize production and improve structural quality.

The project aims to address these challenges with 6 major work packages:

- PG1. Requirements analysis and technology research for superstructure manufacturing. Reducing the size and weight of offshore wind structures through the use of new materials. In addition, it focuses on crucial cyber-physical technologies for superstructure fabrication and specifications for an integrated digital factory model, covering processes such as surface treatment, welding and inspection.

- PG2. New advanced welding processes. Investigation of new welding processes based on hybrid laser and MIG/MAG technology for current and new materials in the offshore wind industry, increasing the productivity of the process and the quality of the product obtained. In addition, the aim is to reduce the preheating area without compromising quality, compare preheating methods, and analyze optimal welding strategies for different materials and thicknesses.

- PG3. New surface treatment processes for offshore structures. Research and development of new surface treatment processes and schemes for offshore wind structures capable of improving process efficiency while ensuring product quality and durability and improving environmental impact through new formulations. This includes improving the application and performance conditions of these systems, modeling and analyzing substrate preparation, parameterizing innovative schemes, and characterizing and modeling external environmental factors.

- PG4. Research on intelligent inspection systems for offshore structures. Research in advanced inspection technologies for large volume offshore structures, seeking to innovate in areas that are currently manual and post-manufacturing by obtaining disruptive processes of intelligent inspection of large surface areas with high stresses associated with the sector through training models with appropriate neural network models.

- PG5. Investigation of digital twin solution for new processes. Design and validation of a data collection, management and analysis strategy for a digital twin. The aim is to model key processes of the production chain by means of this digital twin entity to demonstrate and make an overall estimate of the improvement in efficiency that a generalized digitization would bring.

- PG6. Evaluation of a disruptive manufacturing route for floating offshore wind turbines. The objective is to consolidate the knowledge acquired from the technological validations through “proof-of-concept” experimental stations associated with each previous work package.

GRI Seville will provide an industrial laboratory located in the CIU3A Innovation Center, equipped with the necessary tools such as laser welding cell, surface treatment booths and traditional welding equipment for research, prototyping and proof-of-concept execution. The proofs of concept in the inspection area will be carried out at the Galicia plant, where intelligent systems can be trained for defect detection using real data.